When To Use A Class D Fire Extinguisher? Safety Guidelines

In the realm of fire safety, it's crucial to understand the different types of fire extinguishers and their specific applications. One such extinguisher is the Class D fire extinguisher, designed to tackle a unique type of fire hazard. This guide aims to provide an in-depth understanding of when and how to use a Class D fire extinguisher, ensuring safety and preparedness in the face of combustible metal fires.

Understanding Class D Fires

Class D fires, also known as combustible metal fires, are a distinct type of fire hazard that requires specialized suppression methods. These fires involve burning metals, such as magnesium, titanium, sodium, and potassium, which are commonly found in industrial and laboratory settings. The unique characteristics of these metals make traditional fire suppression methods ineffective and can even exacerbate the fire.

Class D fires are particularly dangerous due to the intense heat and reactivity of burning metals. When exposed to water or certain chemical agents, some burning metals can undergo violent reactions, leading to further combustion or even explosions. This makes the choice of the right fire extinguishing agent critical for effective suppression.

The Role of Class D Fire Extinguishers

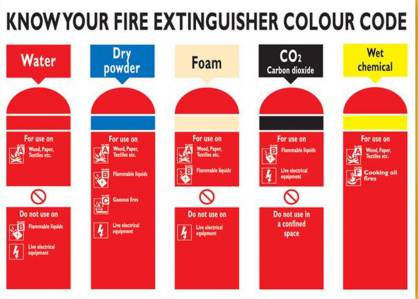

Class D fire extinguishers are specifically designed to combat fires involving combustible metals. They contain dry powder agents that, when applied correctly, can effectively suppress the fire without causing additional reactions or damage to the burning material. The primary function of these extinguishers is to separate the burning metal from the oxygen in the air, interrupting the fire’s combustion process.

The dry powder in Class D extinguishers is typically a specialized type of sand or graphite. When discharged, this powder coats the burning metal, creating a barrier that smothers the fire. The choice of powder depends on the specific metal involved, as different metals require slightly different suppression techniques.

Identifying the Need for a Class D Extinguisher

The key to effective fire safety is identifying the type of fire hazard and selecting the appropriate suppression equipment. In the case of Class D fires, several indicators can help identify the need for a Class D fire extinguisher:

- Metal Shavings or Powders: If your workplace involves metalworking, grinding, or machining processes that produce metal shavings or powders, there's a risk of a Class D fire. These fine metal particles can ignite and spread rapidly if not managed properly.

- Storage of Combustible Metals: If your facility stores large quantities of combustible metals, such as magnesium or titanium alloys, it's crucial to have Class D extinguishers readily accessible. These metals can spontaneously ignite when exposed to air or certain environmental conditions.

- Laboratory Environments: Laboratories often handle small quantities of combustible metals for research or testing purposes. Even a small fire involving these metals can quickly escalate, making Class D extinguishers an essential safety measure.

- Historical Fire Records: If your facility has a history of Class D fires, it's a clear indication that you need to maintain a supply of Class D extinguishers and ensure that your staff is trained to use them effectively.

Proper Usage of Class D Fire Extinguishers

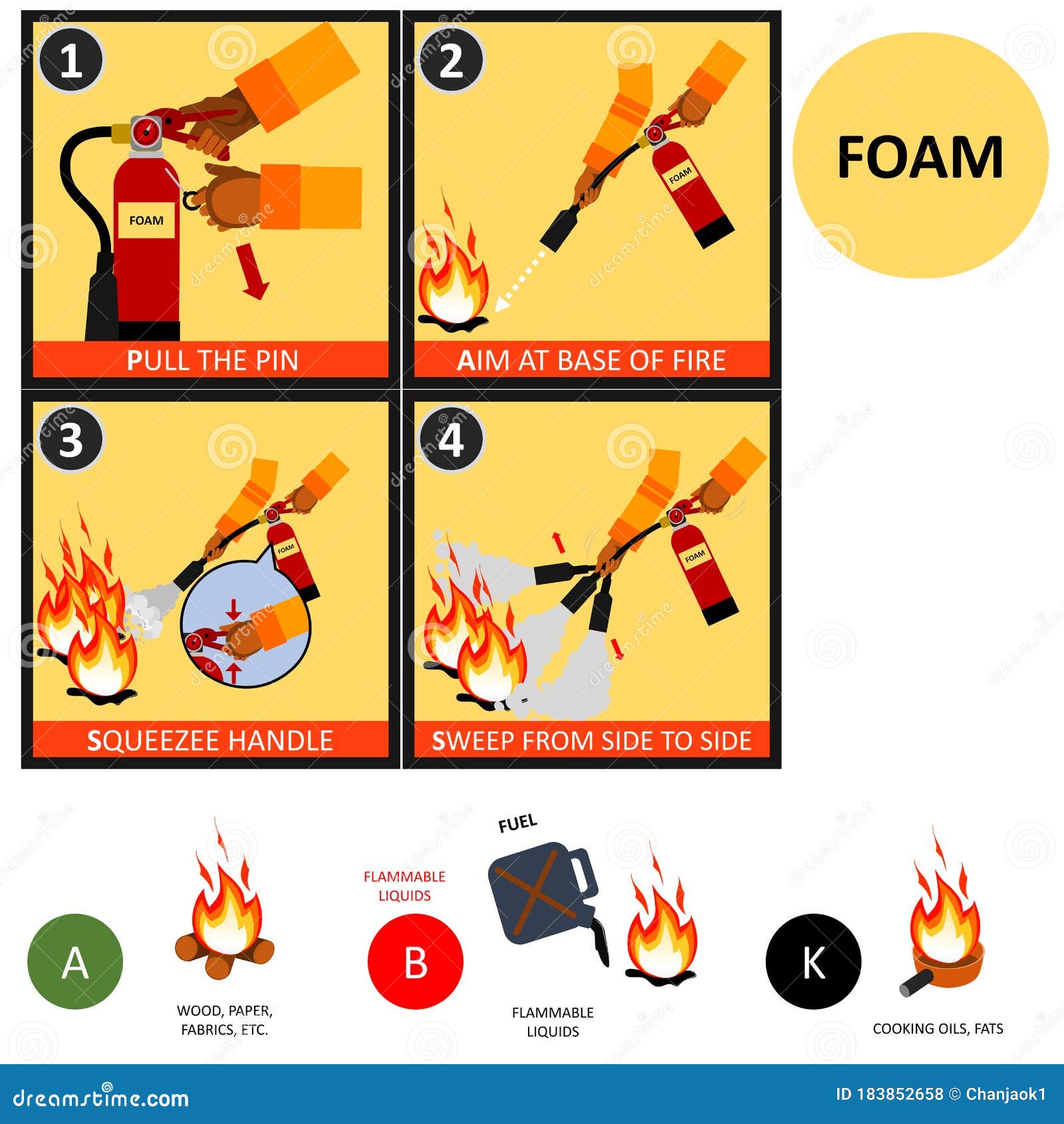

Using a Class D fire extinguisher effectively requires a specific set of steps to ensure safety and successful fire suppression. Here’s a step-by-step guide:

- Identification: Before attempting to extinguish a fire, ensure that it is indeed a Class D fire involving combustible metals. Misidentifying the fire type can lead to ineffective suppression and potential harm.

- Preparation: Put on appropriate personal protective equipment (PPE), including heat-resistant gloves and a face shield, to protect yourself from the intense heat and potential metal fragments.

- Distance and Approach: Stand at a safe distance from the fire, typically at least 6-8 feet away. Approach the fire at an angle, keeping the extinguisher between you and the fire to protect yourself from any potential backdraft.

- Discharge: Aim the discharge nozzle of the extinguisher at the base of the fire, ensuring that the powder reaches the burning metal. A side-to-side sweeping motion can help ensure thorough coverage.

- Coating: Continue discharging the extinguisher until the burning metal is completely coated with the dry powder. This may require using multiple extinguishers, depending on the size of the fire.

- Observation: After coating the metal, carefully observe the fire area for any signs of rekindling. If the fire persists or reignites, repeat the discharge process until the fire is completely suppressed.

- Cleanup: Once the fire is extinguished, it's crucial to clean up the area properly. The dry powder used in Class D extinguishers can be corrosive and may cause environmental hazards if not disposed of correctly. Follow your facility's protocols for proper disposal or recycling of the powder.

Maintenance and Inspection of Class D Extinguishers

Regular maintenance and inspection of Class D fire extinguishers are essential to ensure their reliability and effectiveness. Here are some key maintenance practices:

- Monthly Visual Inspections: Conduct a monthly visual inspection of each Class D extinguisher to check for any signs of damage, corrosion, or tampering. Ensure that the pressure gauge (if present) indicates proper pressure levels.

- Annual Maintenance: Schedule annual maintenance by a qualified technician to thoroughly inspect and service the extinguishers. This includes checking the condition of the extinguisher body, hose, and nozzle, as well as recharging the extinguisher with fresh dry powder.

- Pressure Testing: Depending on local regulations and the type of extinguisher, pressure testing may be required every few years to ensure the integrity of the extinguisher's pressure vessel.

- Replacement: If an extinguisher shows signs of significant damage or corrosion, or if it has been discharged and not recharged, it should be replaced immediately. Never attempt to use a damaged or improperly maintained extinguisher.

Training and Education

Effective fire safety is not just about having the right equipment; it’s also about having a well-trained and knowledgeable staff. Regular fire safety training sessions should be conducted to educate employees on the following:

- The different types of fires and their specific hazards.

- How to identify a Class D fire and the appropriate response.

- The proper use of Class D fire extinguishers, including the steps outlined above.

- Evacuation procedures and the importance of not putting oneself at risk during fire suppression attempts.

Additionally, it's crucial to keep training materials and safety protocols up-to-date and easily accessible for reference.

Conclusion: A Crucial Safety Measure

Class D fire extinguishers are a critical component of fire safety in environments where combustible metals are present. By understanding when and how to use these specialized extinguishers, facilities can significantly reduce the risk of fire-related incidents and ensure the safety of their staff and assets. Regular training, maintenance, and a proactive approach to fire safety are key to achieving this goal.

What are the common causes of Class D fires?

+Class D fires are often caused by sparks, static electricity, or heat sources coming into contact with combustible metals. In industrial settings, metalworking processes like grinding, cutting, or welding can generate sparks that ignite nearby metal shavings or powders.

Can Class D fires spread to other materials?

+Yes, Class D fires can spread to other combustible materials if they are in close proximity. However, the primary concern with Class D fires is the intense heat and reactivity of the burning metal itself, which can pose a significant hazard even without the spread to other materials.

Are Class D fire extinguishers safe to use on all types of combustible metals?

+While Class D fire extinguishers are designed for combustible metal fires, it’s important to choose the right type of extinguisher for the specific metal involved. Different metals may require slightly different suppression techniques, so it’s crucial to consult the manufacturer’s guidelines or seek expert advice for the most effective suppression method.